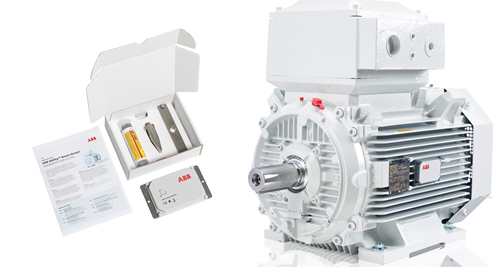

Wireless Condition monitoring for LV motors

The ABB Ability™ Smart Sensor converts traditional motors, pumps and mounted bearings into smart, wirelessly connected devices.

Until today, maintenance teams faced several limitations…

- Maintenance can be fragmented and disconnected, with separate teams for each site (or multiple shift patterns)

- The teams cannot always get contracts to service all of the installed population due to the large number of motors

- In most cases, sophisticated monitoring of LV motors does not make economic sense today

- A significant infrastructure is required, which typically costs more than the motors themselves

- Specialist personnel are needed to install and maintain the monitoring equipment

- Most LV motors are not monitored, and are only maintained when something goes wrong

- Typically, a run to fail approach is taken

How can this solution help to save money and reduce stress?

Fitting the ABB Ability Smart Sensor solution could help to…

- Reduce downtime by as much as 70%

- Service or replace motors before they break down

- Shift unplanned maintenance to planned outages

- Extend lifetime by up to 30%

- Avoid motor failures by timely servicing

- Prevent secondary damage by avoiding breakdowns

- Increase energy efficiency by around 10%

- Create better loading profiles based on energy consumption patterns

- Rationalize the installed base (replace less efficient and over-dimensioned motors)

Welcome to the factory of tomorrow…

If you would like to know more about the ABB Ability Smart Sensor, you can Contact Us or phone 0113 236 1509.